Contact

Us

Archers Company L.L.C.

7527 NE 33rd Dr.,

Portland, OR, 97211

Phone (503) 249-8870

Fax (503) 249-8296

www.archerscompany.com

|

Anti-Vibration Handlebars

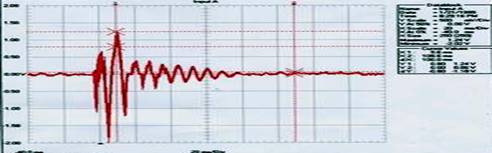

To demonstrate/refute the value of the Hav-Not we devised a test that would measure the actual motion at the bar. We did this by connecting an inductor to the end of the bar then striking the bar with a pendulum mounted mallet. The output from the inductor was input to an oscilloscope for interpretation. Far End Test Without Hav-Not Data Block Cursor Values Name = Input A X1: 9.6 ms Date = 1/21/1995 X2: 109.6 ms Time = 8:29:16 PM dX: 100.0 ms Y Scale = 500 mV/Div Y1: 0.80 1.24 V Y at 50% = 0.00 V Y2: 0.00 0.06 V X Scale = 20 ms/Div dY: -0.80 -1.18 V X At 0% = -40.0 ms X Size = 250 (250) Maximum = 1.24 V Minimum = -2.02 V

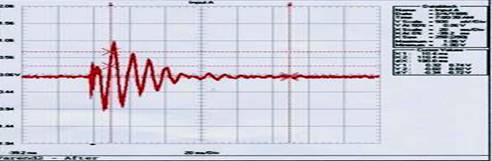

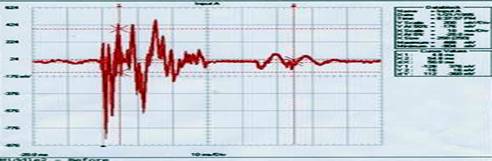

Data Block Cursor Values Name = Input A X1: 10.4 ms Date = 2/4/1995 X2: 110.4 ms Time = 7:00:30 AM dX: 100.0 ms Y Scale = 500 mV/Div Y1: 0.32 0.74 V Y at 50% = 0.06 V Y2: -0.02 0.02 V X Scale = 20 ms/Div dY: -0.34 -0.72 V X At 0% = -39.2 ms X Size = 250 (250) Maximum = 1.06 V Minimum = -1.00 V This first test (shown above), called, "Far End", shows how energy is transmitted from one end of the bar to the other. The bars were struck at their end, with a pendulum mounted mallet; the effect of the mallet strike was measured at the opposite end of the bar. Motion is noticeably reduced, by nearly 40%, in frequency (how quickly the bars vibrate), amplitude (how much or how far they vibrate) and duration (how long they vibrate). Middle Test Before Hav-Not Data Block Cursor Values Name = Input A X1: 4.8 ms Date = 1/21/1995 X2: 54.8 ms Time = 8:37:57 AM dX: 50.0 ms Y Scale = 200 mV/Div Y1: -128 376 mV Y at 50% = -176 mV Y2: -16 16 mV X Scale = 10 ms/Div dY: 112 -360 mV X At 0% = -20.0 ms X Size = 250 (250) Maximum = 488 mV Minimum = -904 mV

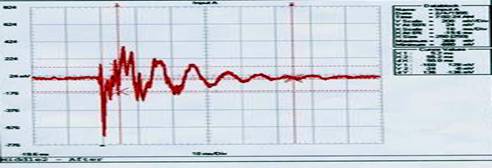

Data Block Cursor Values Name = Input A X1: 5.2 ms Date = 2/4/1995 X2: 55.2 ms Time = 7:02:05 AM dX: 50.0 ms Y Scale = 200 mV/Div Y1: -216 104 mV Y at 50% = 24 mV Y2: -24 -8 mV X Scale = 10 ms/Div dY: 192 -112 mV X At 0% = -19.6 ms X Size = 250 (250) Maximum = 408 mV Minimum = -712 mV

Note: For more information and documentation regarding the testing and test procedures please e-mail me and I’d be happy to respond. My thanks to: Eddie Cole for their help and enthusiasm.

| ||